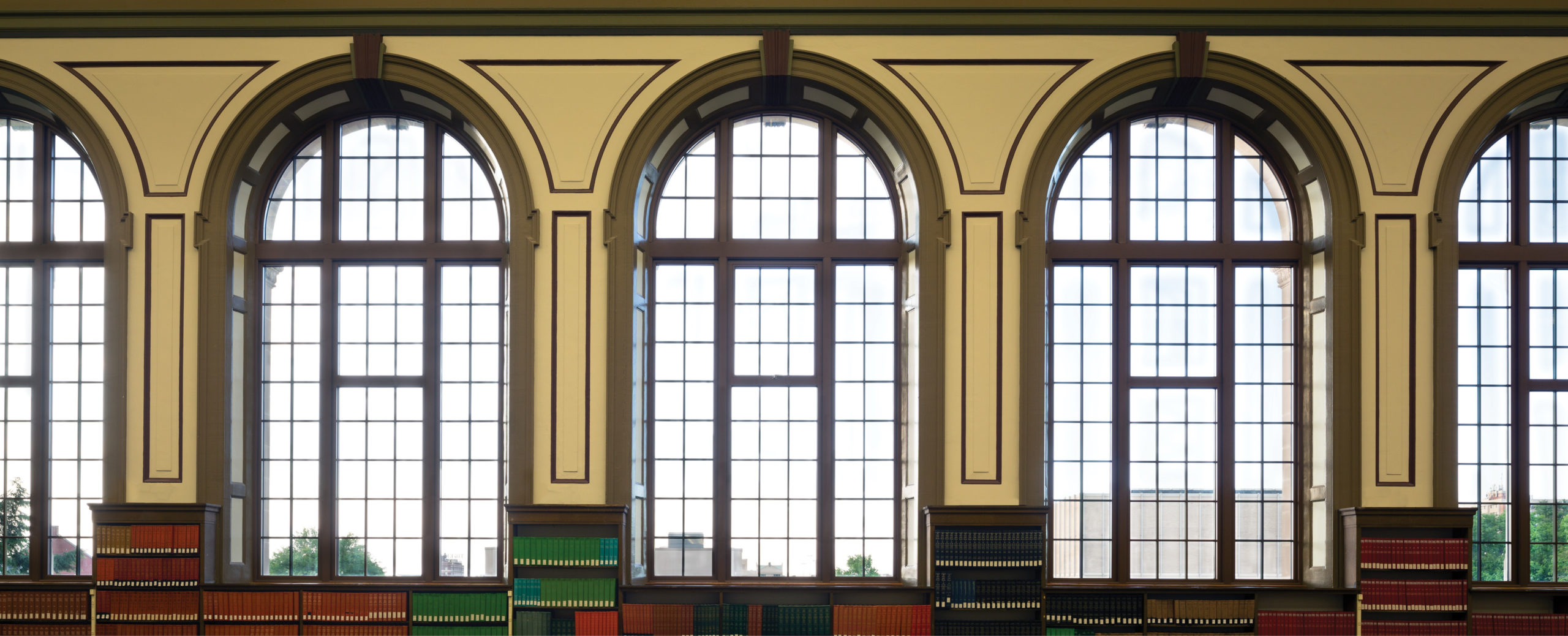

Ellis Library, located in the City of Columbia, is the oldest and largest research library in the State of Missouri. Originally erected in 1913, the main building received a west wing addition in 1935 followed by an addition to the east in 1958. The exterior cladding of the original Beaux-Arts building is made entirely of stone, including all ornamentation. Rows of alternating large, leaded multi story arched windows and engaged columns characterize the dominant architectural features of the building. The signs of moisture infiltration were evident in the numerous cracks in the limestone cladding, spalling stone, displaced keystones. In many instances, incompatible, excessively hard mortars were previously used to point the joints, which caused damage to adjacent, softer masonry through the process of freezing and thawing. Lastly, where building additions adjoin, expansion joints were either executed improperly or not at all. In some locations, expansion joints were filled with mortar or only caulked on the surface; at other locations, convoluted stepping and meandering of expansion joints between dissimilar additions caused cracks in the building’s exterior.

Masonry restoration of Ellis Library commenced in 2020 with the goal of addressing the three causes of building deterioration outlined in the studies – moisture infiltration, improper construction, and erroneous detailing. Fractures in the limestone were injected with custom match DHL and NHL. Spalling stone was repaired with historic patching material, often filling in missing sections of historic ornamentation. Micro-pins, threaded rods, and surgical bone screws were inserted into cracked stone at risk of spalling. These repairs typically occurred at column capitals and bases, and at horizontal projections and overhangs. Large sections of missing stone were infilled as Dutchman repairs with stainless steel dowels and stone sourced from the building’s original quarry. Displaced stones were removed and the crumbling brick walls behind the stone were rebuilt prior to re-anchoring the stone. All mortar joints were raked and tuckpointed with mortar carefully curated to match the color, composition, and texture of the historic joints. Stone adjacent to the existing expansion joint was cut and a new, expansion joint filler was inserted to allow movement and reduce future cracking. Lastly, areas of severe soiling were treated with a four-step chemical process to remove biological and atmospheric stains. The remainder of the building was cleaned with a five-step cleaner, activator, and after-wash process. Extensive efforts were made to ensure a restoration quality befitting the historic building. The qualifications of each mason were scrutinized to meet technical expertise and experience standards. Product representatives consulted in the field to establish appropriate installation of proprietary materials. Lastly, mockups were required for each type of masonry repair in order to control quality and a provide a seamless appearance between the historic façade and areas of repair.